Technologies implemented in the low emission concept studies of the 8,500 TEU container vessel and the 35,000 DWT bulk carrier

1. Advanced rudder and propeller system

A well-designed propeller and rudder system can save up to approximately 4% of the fuel oil consumption. Such a system could be a modern propeller combined with an asymmetric rudder and a so-called Costa Bulb.

A well-designed propeller and rudder system can save up to approximately 4% of the fuel oil consumption. Such a system could be a modern propeller combined with an asymmetric rudder and a so-called Costa Bulb.

With new propeller design methods modern propellers becomes more and more efficient. The Costa Bulb creates a smoother slipstream from the propeller to the rudder. With an asymmetric rudder, the rotational energy from the propeller is utilised more efficient compared to a conventional rudder.

2. Speed nozzle

Normally, nozzles are used to improve the bollard pull on tugs, supply vessels, fishing boats and many other vessels which need high pulling power at low speed.

Normally, nozzles are used to improve the bollard pull on tugs, supply vessels, fishing boats and many other vessels which need high pulling power at low speed.

This new kind of nozzle, called a speed nozzle, is developed to improve the propulsion power at service speed. Using the new speed nozzle concept has a saving potential of approximately 5%.

3. Exhaust gas scrubber system

One way to fulfil the future regulations on sulphur emissions is to install an exhaust gas scrubber. This scrubber system use water to wash the sulphur out of the exhaust gas. Measurements have shown that SOx emissions are reduced with up to 98%. It is not only the sulphur which is reduced, also the content of harmful particles are reduced by approximately 80%.

One way to fulfil the future regulations on sulphur emissions is to install an exhaust gas scrubber. This scrubber system use water to wash the sulphur out of the exhaust gas. Measurements have shown that SOx emissions are reduced with up to 98%. It is not only the sulphur which is reduced, also the content of harmful particles are reduced by approximately 80%.

4. LNG auxiliary engines

Normally, the electrical power in harbour condition is supplied by using auxiliary engines running on heavy fuel or marine diesel. By using auxiliary engines running on LNG (liquefied natural gas) instead of conventional fuel, significant emission reductions can be achieved.

Normally, the electrical power in harbour condition is supplied by using auxiliary engines running on heavy fuel or marine diesel. By using auxiliary engines running on LNG (liquefied natural gas) instead of conventional fuel, significant emission reductions can be achieved.

Emission reductions in the magnitude of approximately 20% on CO2, approximately 35% on NOx and 100% on SOx are the potential of switching from diesel to LNG.

5. Hull Paint

The choice of the right hull paint is essential to keep the resistance at a minimum. Modern anti-fouling hull paint with a low water friction has a fuel saving potential in the region of 3 to 8%.

The choice of the right hull paint is essential to keep the resistance at a minimum. Modern anti-fouling hull paint with a low water friction has a fuel saving potential in the region of 3 to 8%.

The reduction of emissions is proportional to the fuel savings.

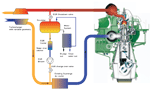

6. Waste Heat Recovery system (WHR)

The waste heat recovery system utilises the heat in the exhaust gas from the main engine. The exhaust gas contains a lot of heat energy which can be transformed into steam. The steam can then be used for heating of the accommodation, cargo areas and fuel oil. The steam can also be used for power generation in a turbo generator. Depending on the configuration, a waste heat recovery system can reduce the fuel consumption by 7 – 14 %.

The waste heat recovery system utilises the heat in the exhaust gas from the main engine. The exhaust gas contains a lot of heat energy which can be transformed into steam. The steam can then be used for heating of the accommodation, cargo areas and fuel oil. The steam can also be used for power generation in a turbo generator. Depending on the configuration, a waste heat recovery system can reduce the fuel consumption by 7 – 14 %.

7. Water In Fuel system (WIF)

The formation of NOx is dependent of the temperature in the cylinder liner. By lowering the temperature the NOx emissions are also lowered. By adding water to the fuel before injection, the temperature in the cylinder will be lowered. This will result in a reduction of NOX by 30-35%.

The formation of NOx is dependent of the temperature in the cylinder liner. By lowering the temperature the NOx emissions are also lowered. By adding water to the fuel before injection, the temperature in the cylinder will be lowered. This will result in a reduction of NOX by 30-35%.

8. Exhaust Gas Recirculation system (EGR)

The formation of NOX emissions can be reduced by lowering the temperature in the cylinder liner of the main engine. One way of lowering the temperature is to recirculate some of the exhaust gas. Some of the exhaust gas is mixed with the scavenge air so that the oxygen content is reduced together with a lower temperature in the combustion chamber. Measurements have shown that this technology have a potential of NOX reductions of approximately 80%.

The formation of NOX emissions can be reduced by lowering the temperature in the cylinder liner of the main engine. One way of lowering the temperature is to recirculate some of the exhaust gas. Some of the exhaust gas is mixed with the scavenge air so that the oxygen content is reduced together with a lower temperature in the combustion chamber. Measurements have shown that this technology have a potential of NOX reductions of approximately 80%.

9. Pump and cooling water optimisation

By using an optimised cooling water system it is possible to save up to 20% of the electrical generated power, corresponding to approximately 1.5% reduction of the total fuel consumption. Studies show that the resistance in the cooling water system often can be reduced. When the resistance is reduced smaller pumps can be used and thereby saving up to approximately 90% of the power needed for pumps.

By using an optimised cooling water system it is possible to save up to 20% of the electrical generated power, corresponding to approximately 1.5% reduction of the total fuel consumption. Studies show that the resistance in the cooling water system often can be reduced. When the resistance is reduced smaller pumps can be used and thereby saving up to approximately 90% of the power needed for pumps.